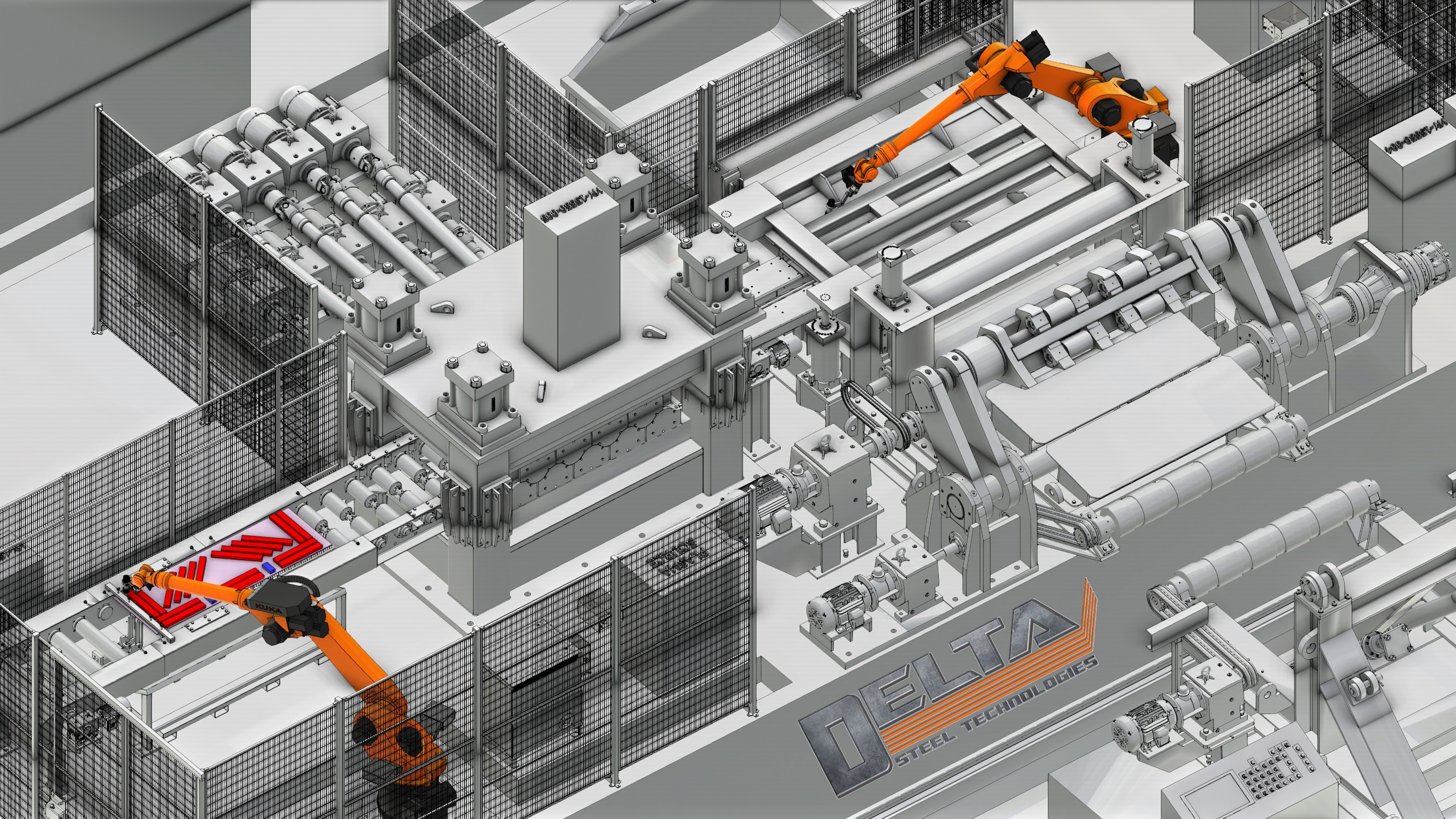

DELTA Steel Technologies, Irving, Texas, recently commissioned a new 1.100” x 80” Hot Band Inspection Line for a mill in Arkansas. DELTA installed two 6-Axis KUKA Robots with Hypertherm Plasma cutting systems. DELTA’s experienced and well-versed team installed this hot band inspection equipment to cut out samples from the coils they produced onsite in order to test the chemistry of the steel, thus increasing quality control and eliminating excess costs.

The KUKA robots are controlled from the main operator’s console through the PLC without the need of the robot teach pendant. The automated system is designed to allow the operator to simply push a preset button and the robot will execute a specific cut command without the need of any programming. The presets include all the necessary steps to do the operation and move back to the “Home” position with the single push of a button. The Hypertherm Plasma Unit combines fast cutting speeds, rapid process cycling, quick changeovers, and high reliability to maximize efficiency. The superior cut quality means that samples can go directly from the cutting table to laboratory without expensive secondary operations. DELTA’s innovative 21st century technology and ability to “think outside the box” can help anyone enhance productivity and certify quality to compete in today’s rapidly evolving market.