Efficient scrap handling is crucial for steel processors looking to maximize productivity, ensure operator safety, and enhance profitability. Let’s explore the two popular options—Scrap Choppers and Scrap Winders—and help you make the best choice for your operations.

Scrap Winder:

Advantages:

- Compact design, ideal for facilities with limited space.

- Easily integrates into existing lines without extensive modifications.

- Operates quietly, reducing noise levels on the shop floor.

Considerations:

- Requires line stoppages for scrap coil removal, interrupting production.

- Manual threading increases downtime and operator intervention.

- Limited effectiveness with extremely thin, thick, or high-tensile materials.

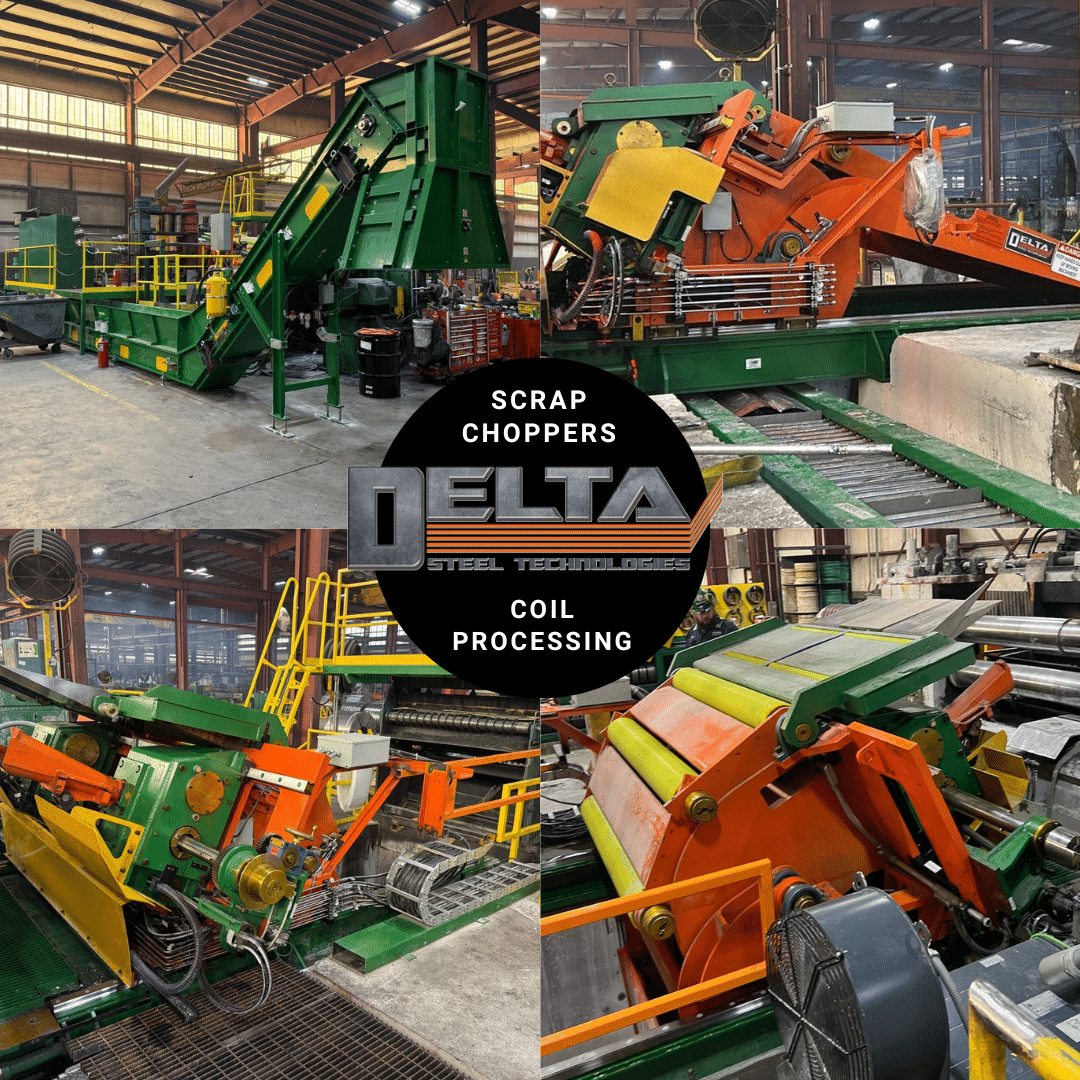

Scrap Chopper:

Benefits:

- Continuous, uninterrupted operation significantly boosts productivity.

- Automatic scrap handling reduces downtime, enhancing throughput and labor efficiency.

- Improves operator safety by minimizing manual intervention and exposure to sharp materials.

- Easier scrap management, with improved transportation and higher resale value.

- Ideal for a wide range of materials, especially thicker and high-strength steels, aluminum, and stainless steel.

Considerations:

- Requires larger installation space due to additional conveyors and bins.

- Produces higher operational noise and requires periodic maintenance.

Which is Right for You?

Scrap winders may fit operations running moderate gauge materials with limited space and lower production demands. Conversely, processors aiming for uninterrupted high-speed production, reduced safety risks, and optimized scrap value should consider a scrap chopper.

Ready to upgrade or explore your options? Contact Delta Steel Technologies today to find the perfect solution tailored to your operation.